122 House Keeping The inside of the oven top of the oven and sides of the oven should be kept clean and free of debris. This is sufficient for most paint and powder applications although there are a few coatings Teflon for.

Pdf Systematic Approach To Industrial Oven Optimisation For Energy Saving

Temperature Range Identify the temperature you need your product to heat to and determine your minimum and maximum operating temperatures.

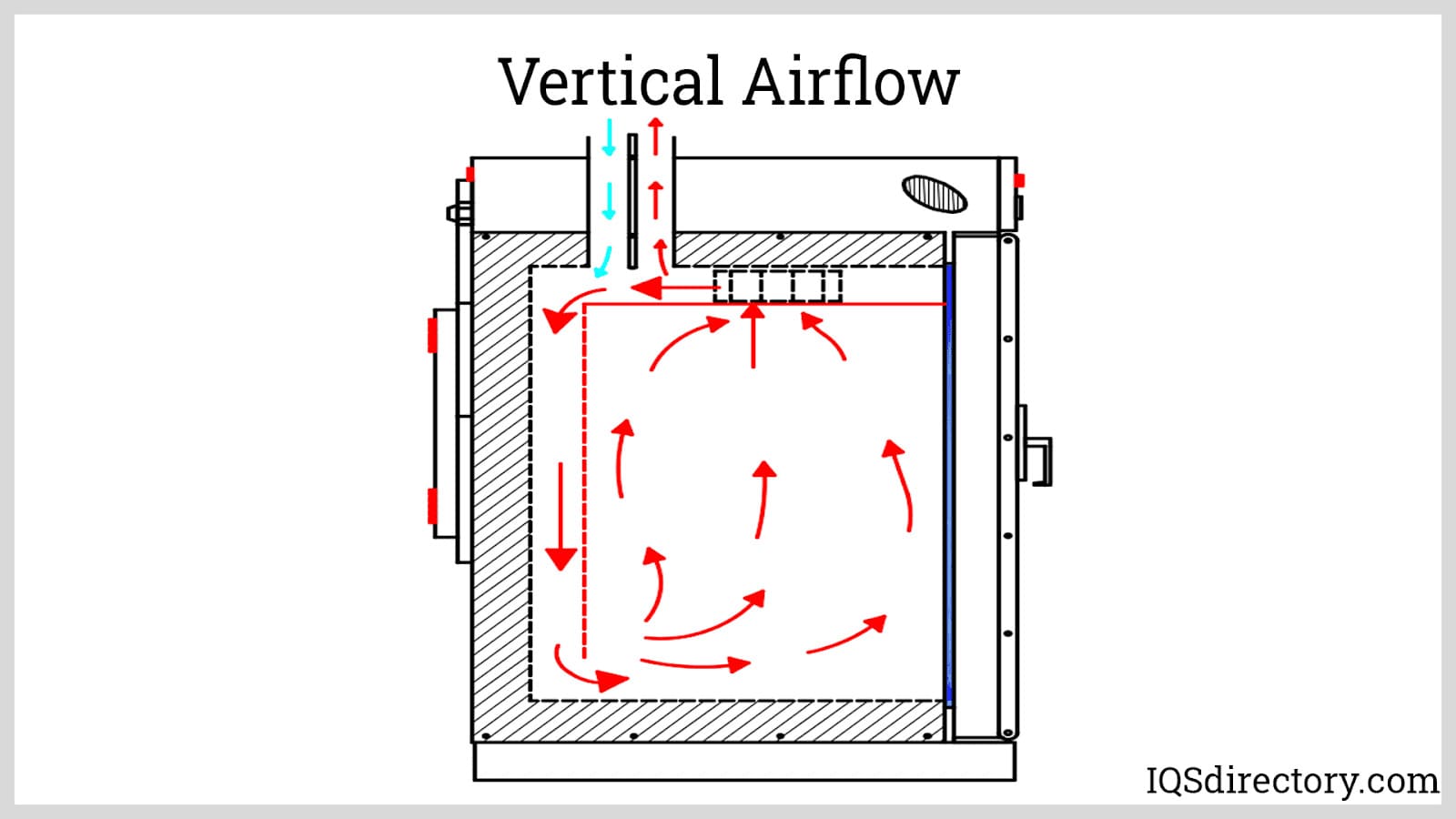

. UAny specific cool-down requirements. Additionally there are also six primary types of airflow which is essential to configure with product-loading. The oven is designed to replace 20 of the air with fresh air in order to maintain low levels of CO but caution should be used in case of an unsafe CO level inside of oven.

To select a curing oven it is first necessary to determine the time and temperature your coating requires in the oven. A corresponding flow of cooler ambient air will enter the oven to replace the warm exhausted air. These ovens work on the principle of heat transfer through convection wherein hot air is circulated through the heating chamber as heat transferring media.

Kalp ve Damar Cerrahisi KVC Uzmanı. Operation of industrial ovens and furnaces. For more information on any of our commercial oven services or products including oven design sales and installation or if you still have questions about the type of industrial oven or furnace you need please call Precision Quincy at 302 602-8738 or request a quote.

Refrigeration Refrigeration systems are. Furnaces vens can be field-audited to satisfy O CSA via ESA and UL 508 inspections and certifications. Typically oven cool-down is achieved by exhausting heated air from the oven.

Suitable for both industrial practitioners and undergraduates this title is designed to help the reader better understand the principles governing furnace design and operation. Most industrial ovens designed for curing are rated at a maximum of about 500 degrees Fahrenheit 260 degrees Celsius. 90 532 375 96 58.

All Sahara Industrial Ovens are built to meet these requirements vens are built to meet NFPA Class A o 70 and 79 standards for ovens and. Our goal is to be the right partner for the growth and renovation of our Customers. UWhether the heat-up rate needs to be controlled or if the product can be allowed to reach temperature as quickly as possible.

A new batch oven has been constructed to mimic industrial convection tunnel ovens for research and development of continuous baking processes. The two main principles of the industrial oven are the heat sources and airflow patterns. The hot air transfers heat onto the component thereby attaining the desired temperature.

Oven was design ed and was fabricated with an outer dimension of 450 mm length 350 mm width 380 mm height made up stainless steel and the inner dimension of 380 mm length 310 mm width 340 m. Contact our sales and engineering professionals to clarify your. The methods of heat transfer in gaseous liquid or solid mediums or between two mediums can.

Propose design make and install medium and large industrial systems the Polin Industrial Line guarantees quality and reliability in the mixing make-up baking cooling and packaging of bread biscuits and pastry products. The oven design will need to have sufficient heating capacity to bring the product to the desired temperature within the specified time. If the cool-down rate requires no control the only need is to size the exhaust fan large enough to remove the necessary amount of heat in the required time.

Temperatures in the oven can exceed 400 F. Customers who are worldwide. If necessary industrial conveyor ovens can be equipped for 120240 dual voltage operation.

Process ovens can obtain their heat from an electric gas steam water or oil source among others. Industrial Ovens Spray Booths Airflow Group. The process parameters air flow air temperature air humidity height of baking area and the baking band velocity are therefore highly controllable and adjustable over a wide range of settings.

Ad Manufacturing Industrial Ovens And Other Heating Equipment Since 1973. The oven design will need to have sufficient heating capacity to bring the product to the desired temperature within the specified time. 31 Mechanisms of heat transfer.

Pdf Dynamic Heat And Mass Transfer Model Of An Electric Oven For Energy Analysis

Neufert Kitchen Design Guidelines Small Space Design Design

Powder Coating Oven Wall Frame Powder Coating Oven Powder Coating Diy Powder Coating

Rocket Oven 2018 Plans Download Digital Market Forum At Permies Rocket Stoves Rocket Stove Design Diy Rocket Stove

Convection Ovens An Overview Sciencedirect Topics

The Rocket Fired Barrel Oven Firespeaking Wood Fired Oven Barrel Oven Rocket Stoves

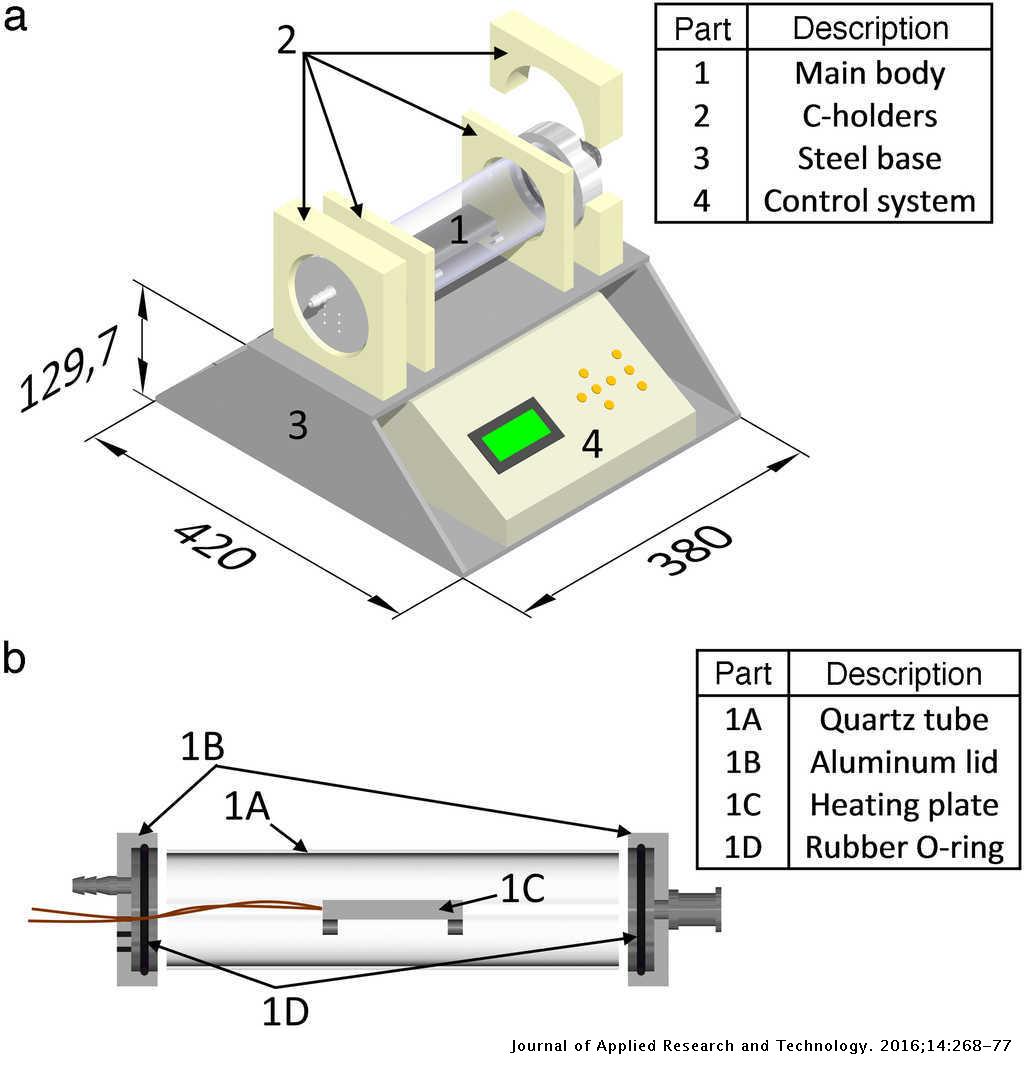

A Dedicated Electric Oven For Characterization Of Thermoresistive Polymer Nanocomposites Journal Of Applied Research And Technology Jart

0 comments

Post a Comment